- Home

- How it works How it works

-

Drone shop

- All products

- Your shopping cart

- 🔥 Hot-Deals

- DJI Mavic range

- DJI Phantom range

- DJI Matrice range

- Thermal camera drones

- Crop spraying drones

- FPV racing drones

- Underwater drones

- Fishing drones

- DJI Agras (spray drone) parts

- Drone accessories

- Drone Rental

- Drone Repair Services

- About the DFH drone shop

- Stock photos

- Drone Finance - Get Quotes

- Drone Insurance

- Dry Hire Dry Hire

- Industry uses

-

Industry uses

- All Uses

- Construction sites (e.g. fly overs for progress reporting)

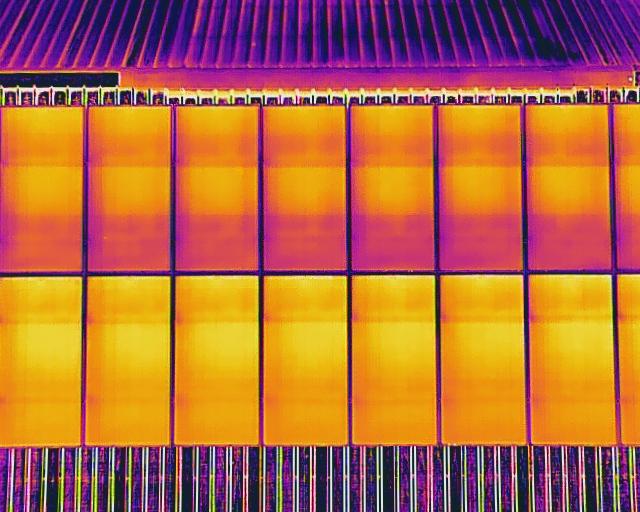

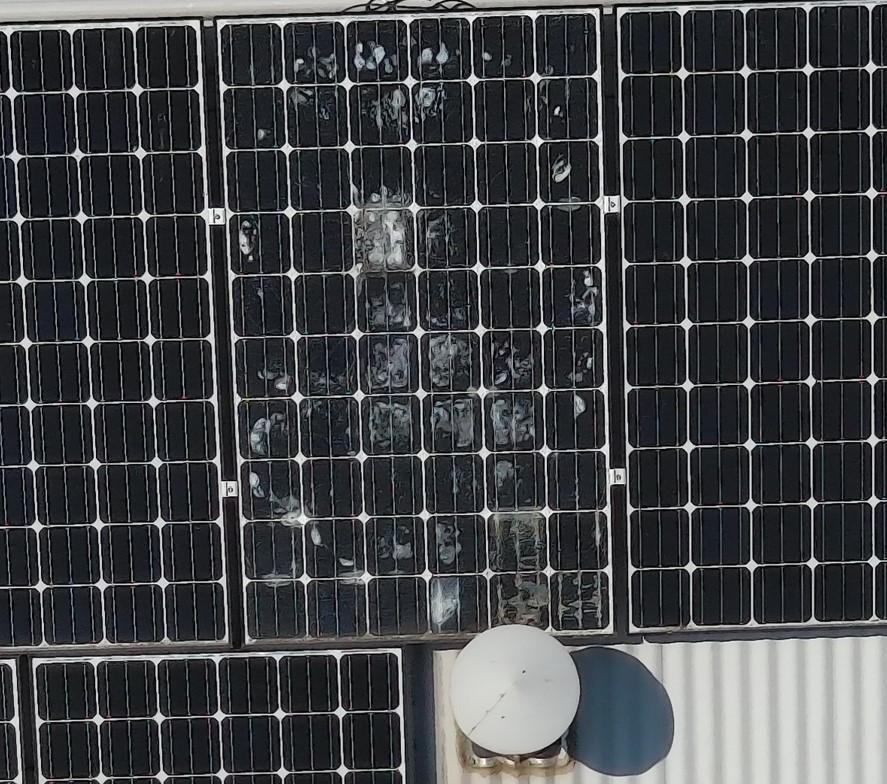

- Asset & building inspection (e.g. roof or tower inspection)

- Agriculture (e.g. crop health or spot spraying)

- Environmental survey (e.g. mapping a waterway)

- Mine sites, landfill & quarry (e.g. volume calculations)

- Film industry (e.g. TV commercial)

- Real-estate (includes residential & commercial)

- Events (e.g. festival, corporate event, wedding)

- Small business promotion (e.g. for website & social media)

- Drone light shows

- Case studies

- Weekly news

- Our articles

-

Spray Drones

- Spray drones for sale

- Why the T50 is the best spray drone

- 4 reasons why spray drones are booming

- 5 reasons to consider DFH as your supplier

- 17 reasons to choose a DJI spray drone

- Spray drone case studies & articles

- Image gallery: spray drone demo days

- Mapping drones for sale (regular images & NDVI)

- Thermal drones for sale (animal spotting etc)

- Recommended generators

- Finance providers - get quotes

- Drone Insurance

- CASA requirements for spraying

- T40 Type Rating Certification

- Chemicals license requirements (ChemCert tickets etc)

- Parts store (spray drone parts)

- DFH Batch Master

- Online Training for T40 & M3M

- View upcoming ag. demo days

- DJI Agriculture Authorised Service Center

- Pilots on map

- Pilot list

- Training courses Training courses

- Contact

- Contact

- Pilot Account

- 1300 029 829 All Enquiries